Parts and components factory

about us

Founded in 1996,  is a company manufacturing parts and assembly components. It collaborates with companies in the mechanical, aerospace, electro-avionics, medical and industrial design sectors, with solutions for the design and manufacturing of parts, discontinued spare parts and industrial supplies to continue

is a company manufacturing parts and assembly components. It collaborates with companies in the mechanical, aerospace, electro-avionics, medical and industrial design sectors, with solutions for the design and manufacturing of parts, discontinued spare parts and industrial supplies to continue

company mission

"We believe that the production needs are increasingly aimed at containing costs while maintaining final quality " to continue

advantages

Our production solutions offer the following advantages :

- Feasibility studies, manufacturing proposals and free estimates.

- Supply of raw parts or parts complete with machining, treatments and finishes, ready for assembly and use.

- Engineering services included.

- Supply of standard or custom components and equipment for the assembly and operation of the product.

- Competitive prices, without requiring minimum order quantities (M.O.Q.) and shipping costs to continue

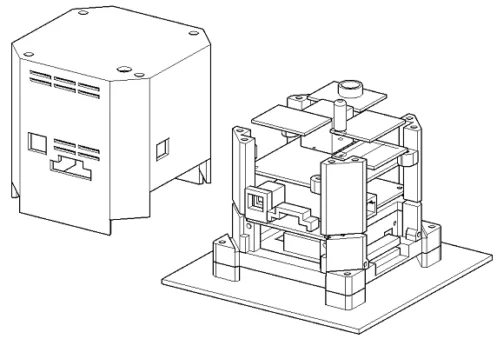

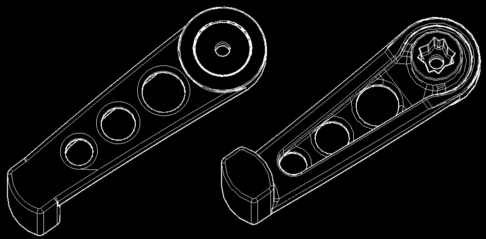

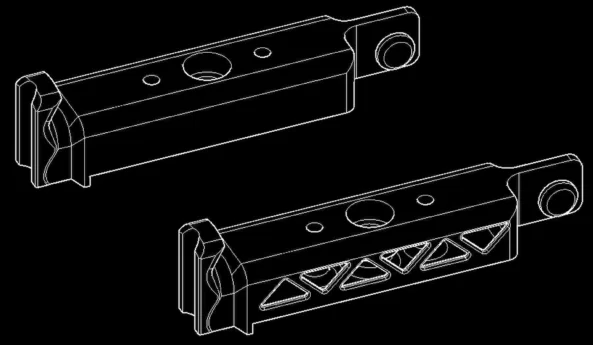

manufact

replica

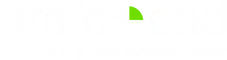

In case of unavailability of C.A.D. drawings and 3D models of the part to be manufactured (e.g. discontinued spare parts), we create the replica through 3D scanning - reverse engineering and manufacturing to continue

REPLICA

REPLICA

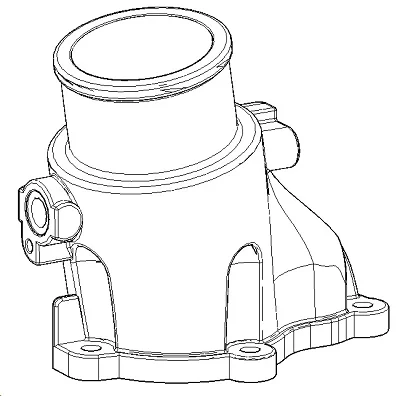

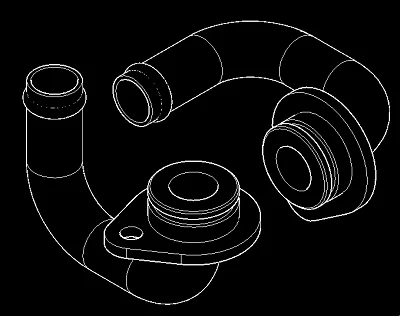

technologies

In the manufacture of parts, we use both traditional technologies such as metal casting and injection molding, as well as innovative technologies such as 3D printing to continue

contact